Gyrobob

Serious Thumper

Offline

Offline

Posers ain't motorcyclists

Posts: 2571

Newnan, GA

Gender:

|

The EMGO muffler in the RYCA kit is not a muffler. It is a noisemaker. The fiberglass "packing" in the thing is almost as durable as toilet paper.

I tried replacing the packing with stainless steel packing and it was still too loud, and was forcing all the exhaust to flow through one perforated cup.

I added a sink strainer mod at the outlet of the muffler, and that helped a little,.. but the situation with the packing was still worthless.

Now, I have taken out all the packing, and added two pieces that redirect the flow so that the noise has to go into the muffler, pass from the inside to the outside of the core, then back into the core, then back out, then back in, then through a technologically advance sink strainer to further disperse the noise, then out. The principle is to send the sound waves through different compartments with different sound properties to dampen out the sound without simply trying to absorb it.

I tried it out this morning. It works. Yay. The tone is still manly, but the horrendous obnoxious harley-like CRACK is not there. At full throttle it is still pretty throaty, but not as loud. During normal acceleration in traffic, the exhaust noise is tolerable, and sounds nice. I don't feel like I am pissing off everyone within 100 yards.

Here's what EMGO calls packing. That is a thin layer of fiberglass loosely held in place with some safety wire. That stuff was gone within 20 miles of the first ride and the noise was even louder.

Here's what it looks like with the packing gone and the two pieces I made to make a packing-free muffler.

-- The outer ring has a few small holes in it, and is to be welded to outside of the perforated core.

-- The washer I am holding is a concave washer with a four 5/32" holes drilled into it in addition to the original center hole, and is to be welded to the inside of the perforated core.

-- The concave washer is supposed to act like a crude parabola to reflect the noise wave back up the pipe, like Flowmaster does in their high-flow mufflers.

-- Not shown is the sink strainer to be MIG welded on the output end of the assembly.

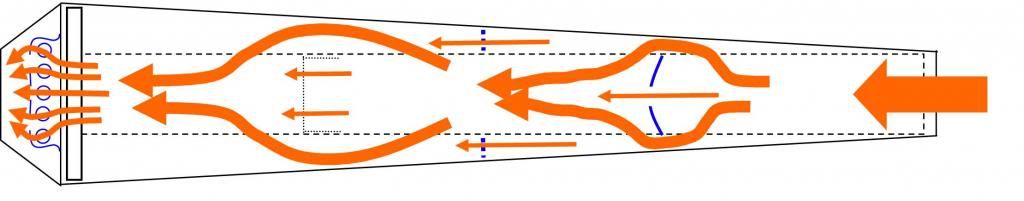

Here's a drawing of how the exhaust flows. The blue parts are what I added.

Here's what it looks like after a 50 mile ride. From left to right:

-- sink strainer

-- about 4" to the right of the strainer, the original perforated cup inside the perforated core.

-- baffle around the outside of the perforated core, a very large washer MIG welded to the core.

-- concave baffle MIG welded inside the perforated core.

End view showing the concave baffle (washer) MIG welded inside the core.

The whole shebang inserted in the muffler shell, with a good view of the sink strainer MIG welded on the end of the baffle assembly.

Fully assembled.

|